Flat Bottom Box or Doypack bags?

We have introduced innovative FLAT BOTTOM BOX packaging to our offer, which is a great successor to the popular Doypacks. Both Flat Bottom Box and Doypack belong to the family of bags and string packaging, which makes them versatile and can be used in many industries.

Stand-up bags

Flat Bottom Box packaging are stand-up bags with a formed rectangular bottom, ensuring greater stability than Doypack, which has a “teardrop” bottom. These modern packaging looks attractive on the store shelf and offers more space for labeling. Additionally, the appearance of the packaging is more attractive.

Functional accessories

Box bags are equipped with more functional accessories than standard Doypacks. They have rounded corners, which improves the aesthetics of the packaging, as well as a laser notch and an Easy Open notch, enabling easy and aesthetic opening of the packages. In the store’s standard offer, Doypacks have straight corners and a regular notch.

Rounded corners and laser cuts are only available in the Doypack PRO version.

Both types of packaging are equipped with a practical zipper that allows you to open and close the package multiple times. This effectively protects the contents against moisture, dirt and microorganisms. Box packaging is perfect for storing products at home, while also facilitating the organization of space. This advantage will make the consumer reach for the product in this packaging – an advantage over the competition!

Accessories:

- zipper

- notch Easy Open

- laser cut

- rounded corners

- rectangular bottom

Prints

We can provide both types of packaging with individual printing, with Doypack being the cheaper solution in this category.

Sizes and material

Flat Bottom Box packaging is extremely universal and functional, available in three sizes and various materials.

FLAT BOTTOM BOX METALIZA are made of PET12met/PE60 laminate. Metallized packaging guarantees a high barrier to water vapor, excellent mechanical strength and a high barrier to oxygen. Perfect for packaging dry, loose, dusty, lumpy and fatty products that require protection from light. Perfect for packaging products such as dried herbs, herbal and vegetable spices, vegetables and fruits: dried and freeze-dried, food concentrates, desserts (puddings, jellies), drinks, starch, dried and fried potato products (e.g. crisps, puffs), milk powder, gruels and porridges, chewing gum, dog food…etc.

Available sizes: ~100x80x215mm, ~120x90x255mm, ~150x105x330mm

FLAT BOTTOM BOX NATURA MET are made of PAP40/PET12met/PE60 laminate. The ecological-looking packaging stands out on the store shelf. It has similar properties and applications to its metallized counterpart. Sizes as above.

FLAT BOTTOM BOX TRANSPARENT are made of PET12/PE60 laminate. The transparent packaging is characterized by excellent mechanical strength and medium barrier to water vapor and oxygen. Perfect for packaging liquid, semi-liquid, dry, loose, dusty, lumpy and fatty products.

Perfect for packaging products such as sauces, marinades, pickled vegetables, juices, mousses, syrups, pastry products, sugar, cocoa, halva, roasted nuts, dried fruit, candies, starch, dried potato products… etc. Dimensions as above.

Certifications

Both types of packaging, i.e. Flat Bottom Box and Doypacks, are approved for contact with food.

Manual or machine packaging

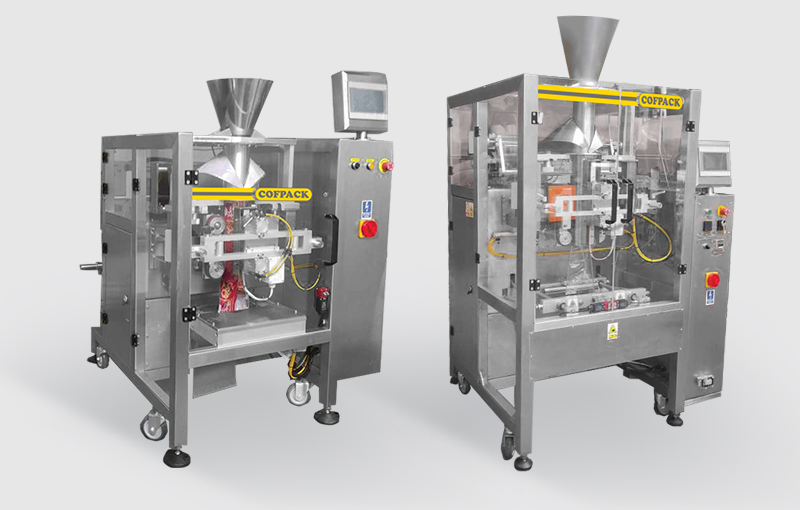

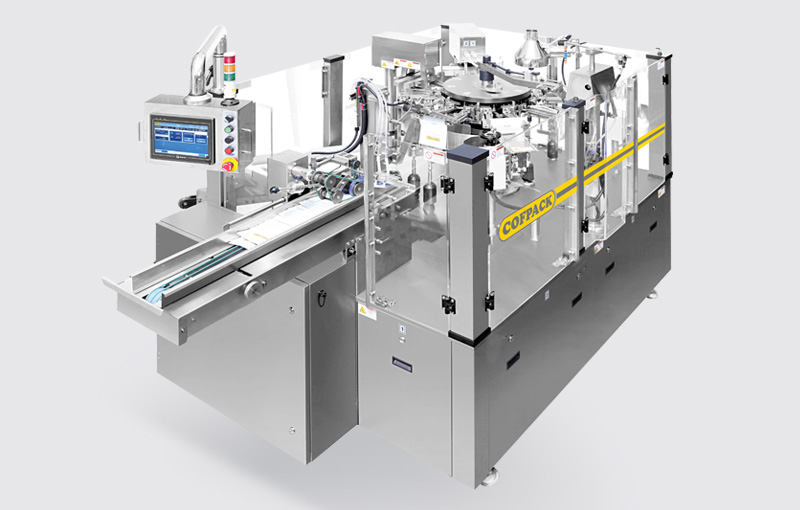

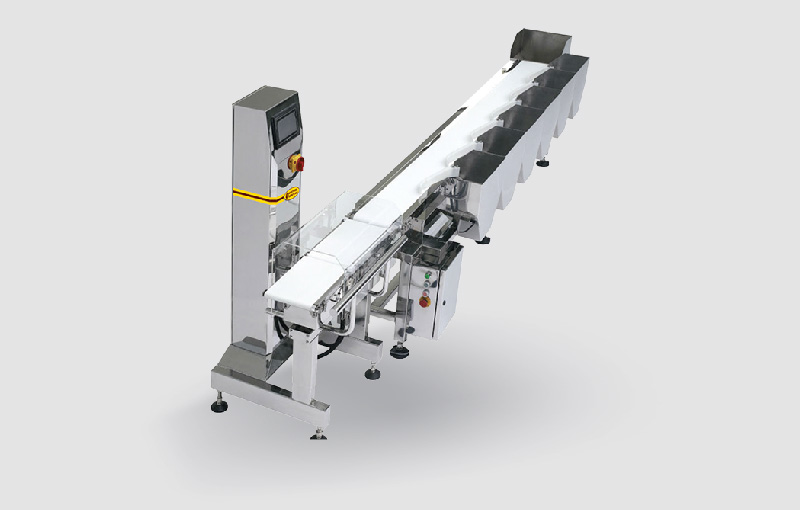

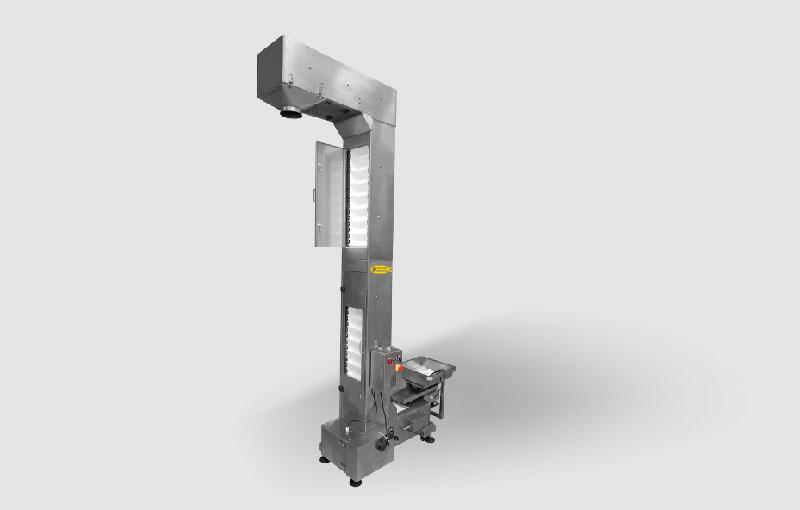

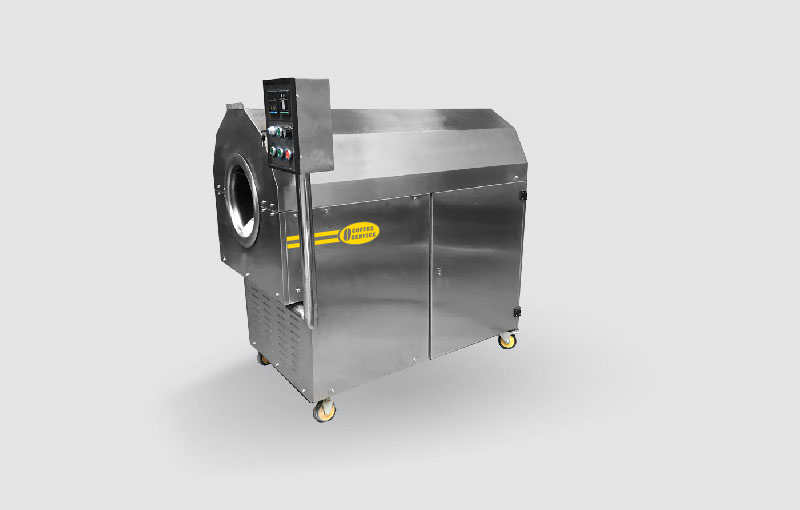

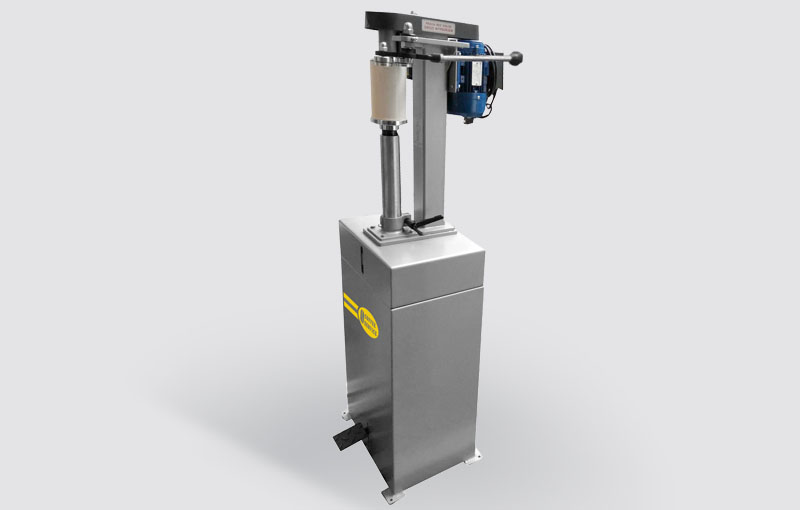

Flat Bottom Box and Doypack packaging are dedicated to manual packaging or automatic packaging into ready-made bags. Machines such as COFPACK DOYPACK K 8-45 and COFPACK DOYPACK C 210 L/SC work perfectly.

In our company, we will design a complete packaging line with appropriate efficiency and packaging quality. Automatic packaging machines for ready-made bags do not require investment in additional tools (e.g. foil forming sets or sealing jaws), which contributes to lower production costs. They are very universal, enabling quick size setting and packaging of various products in many types of packaging of various sizes and shapes.

New is better!

Doypack packaging has been dominating the market for a long time and is often used as complementary packaging. Therefore, it is worth using new packaging and a new shape to stand out on the market. Customers are always willing to choose what is new, modern and better. Today’s market is very demanding in terms of packaging functionality, and the Flat Bottom Box packaging is a step forward that meets the needs of consumers.