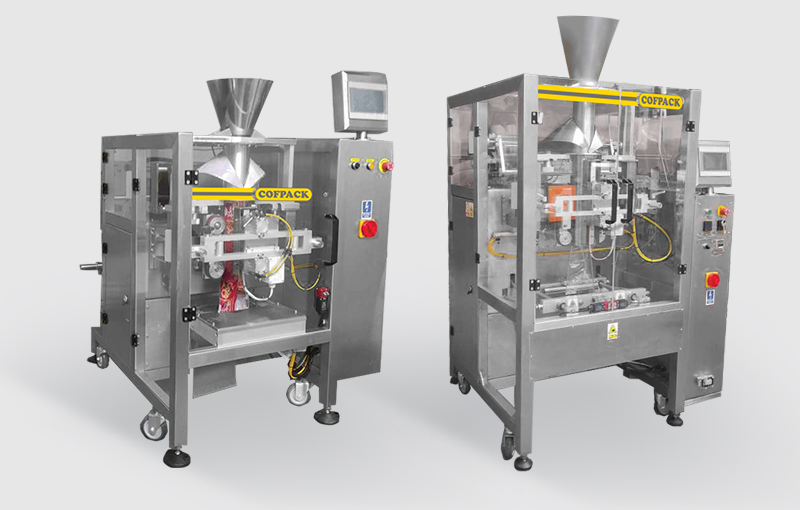

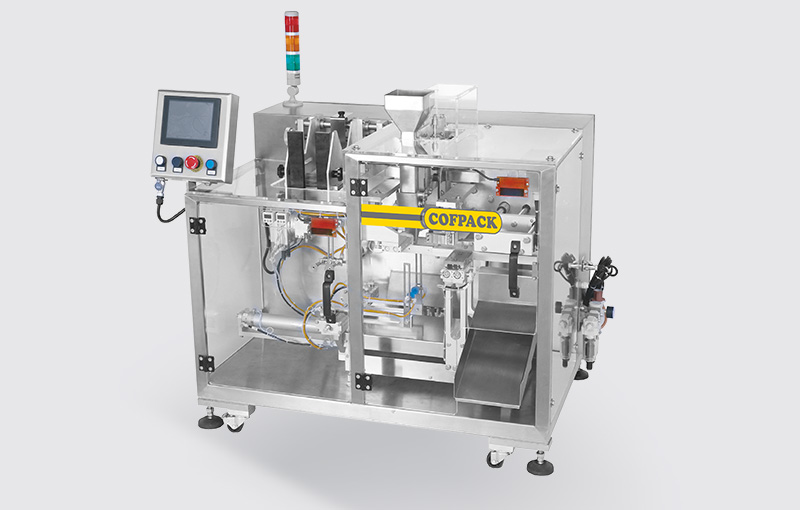

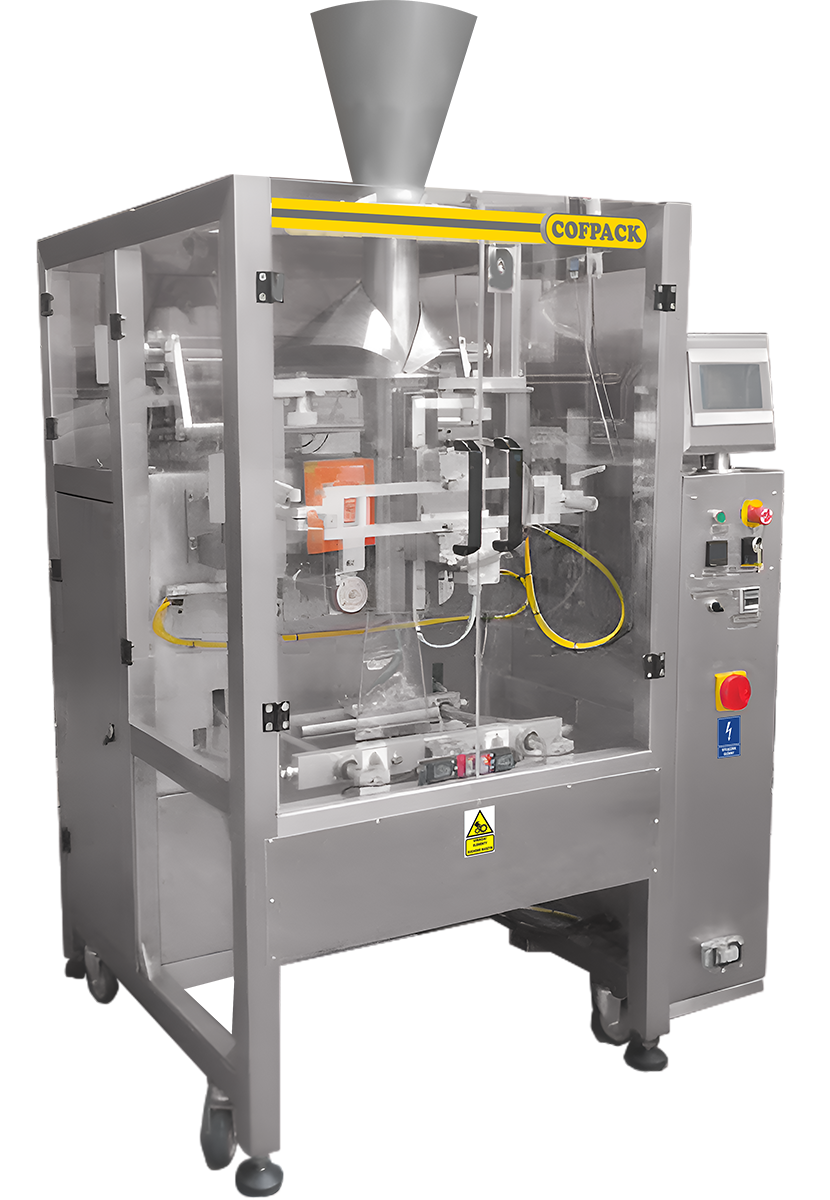

Vertical packaging machines COFPACK P/S

Vertical packaging machines COFPACK P/S – are fully automated devices that allow you to pack products in various types of heat-sealable foil. These are VFFS machines, where the foil moves vertically, folds in a forming set, and then is sealed to form a package into which the product is dosing. After welding and cutting, a package with the product is created. Depending on the model of the packing machine, we can use foil with a width of 140 mm to 800 mm, and even up to 1200 mm on request. The standard type of packaging formed on these machines is a flat pouch, and optionally a gusset pouch or BOTTOM type packaging. The machines can work with various types of fillers (combination weigher, auger fillers, sauerkraut fillers, etc. ) The versatility and small dimensions save the production space, and the use of servo drives increases efficiency, reducing production costs. Packaging machines can be part of the packing line.

The packaging machine COFPACK P/S EKO model is an economical and simplified version of the COFPACK P/S packing machine. Basic differences between packing machines:

COFPACK P/S | COFPACK P/S | COFPACK P/S EKO | |

made of | INOX 304 | INOX 304 | INOX 201 |

servo drives number | 4 | 2 | 1 |

mechanical | to 180 cycles/min. | to 180 cycles/min. | to 60 cycles/min. |

controller | Simens | Simens | Delta |

side folding | pneumatic | pneumatic | mechanical |

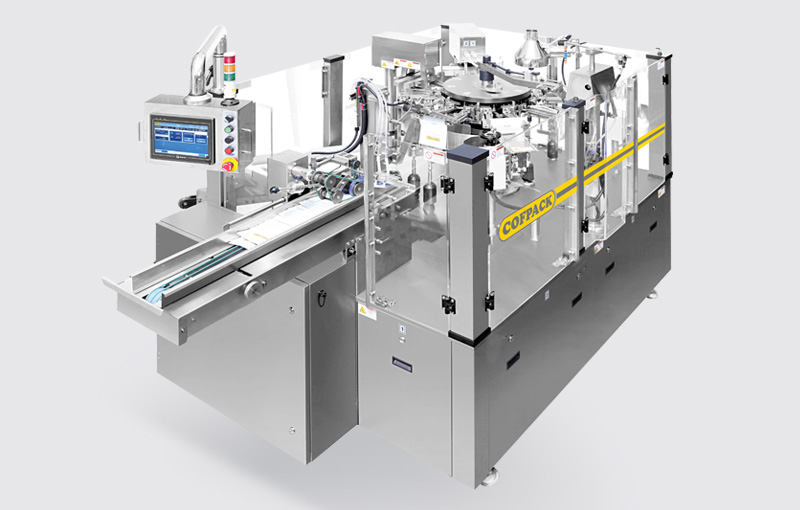

COFPACK P/S 180/510 CONTINUOUS

4 servomotors

![]() ADDITIONAL ADVANTAGES:

ADDITIONAL ADVANTAGES:

- high mechanical capacity – up to 180 cycles per minute

- quick-change forming sets

![]() ADDITIONAL OPTIONS:

ADDITIONAL OPTIONS:

- nitrogen gas device NGO/S

- tear notche device NO/S

- static charge eliminator DE/S

- gusset device SFB/S

Packaging machine COFPACK P/S 90/400

packaging variants:

they are used for packing, among others:

flour, groats, sugar, spices, sweets, dried fruit, frozen foods, corn crisps, cotton candy, snacks, pet food, powdered milk, protein products, etc.

mobility

contrast data printer

nitrogen gas device

bag support

gusset bag device

chain bag device

air expeller

euro hole punch device

BOTTOM seal

static charge eliminator

tear notche

inside valves applicator

![]() ADDITIONAL ADVANTAGES:

ADDITIONAL ADVANTAGES:

- small dimensions

- high efficiency thanks to the use of two servo drives

- easy and quick replacement of the forming set

- electronical roll unwinding

- automatic film tracking

![]() ADDITIONAL OPTIONS:

ADDITIONAL OPTIONS:

- impulse sealing device

- narrow jaw

- additional forming set

- printer

- UV lamp

- heating the control cabinet

Packaging machine COFPACK P/S 60/500 EKO

packaging variants:

they are used for packing, among others:

flour, groats, sugar, spices, sweets, dried fruit, frozen foods, corn crisps, cotton candy, snacks, pet food, powdered milk, protein products, etc.

mobility

bag support

euro hole punch device

nitrogen gas device

![]() ADDITIONAL ADVANTAGES:

ADDITIONAL ADVANTAGES:

- small dimensions

- easy and quick replacement of the forming set

- electronical roll unwinding

- automatic film tracking

![]() ADDITIONAL OPTIONS:

ADDITIONAL OPTIONS:

- mechanical gusset bag device

- printer

- heating the control cabinet

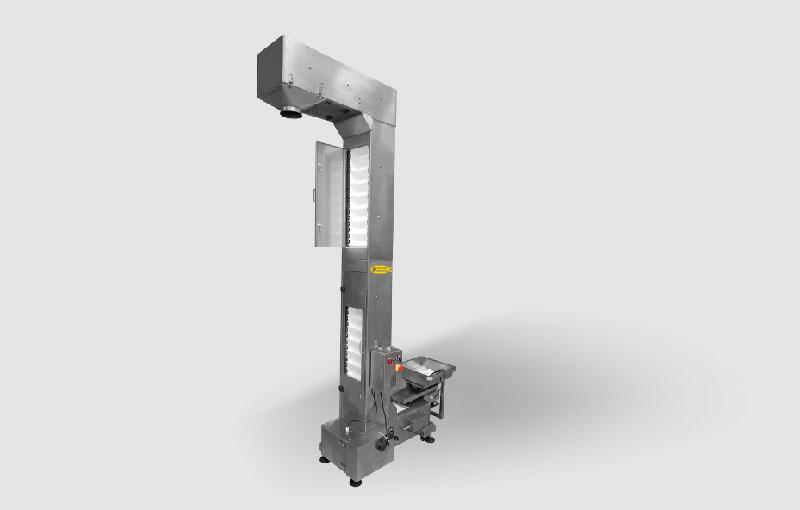

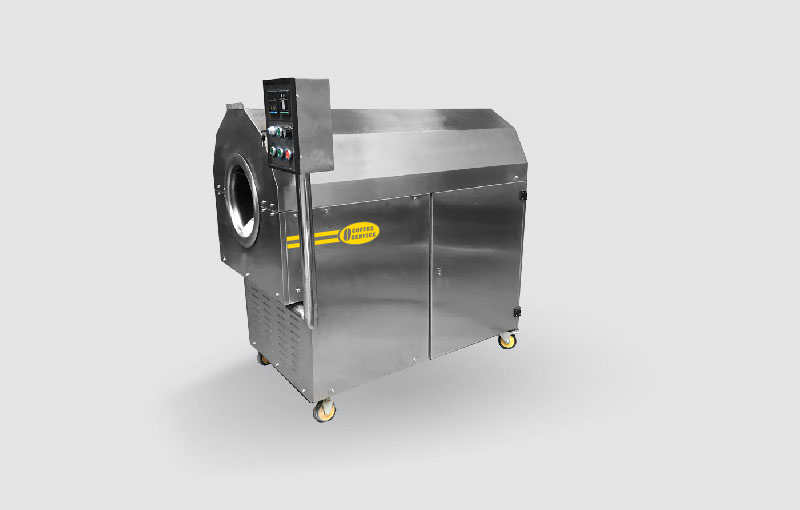

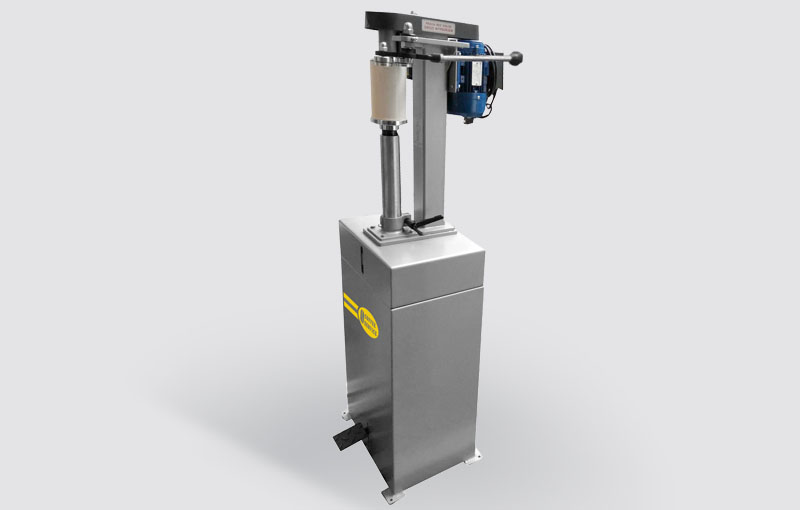

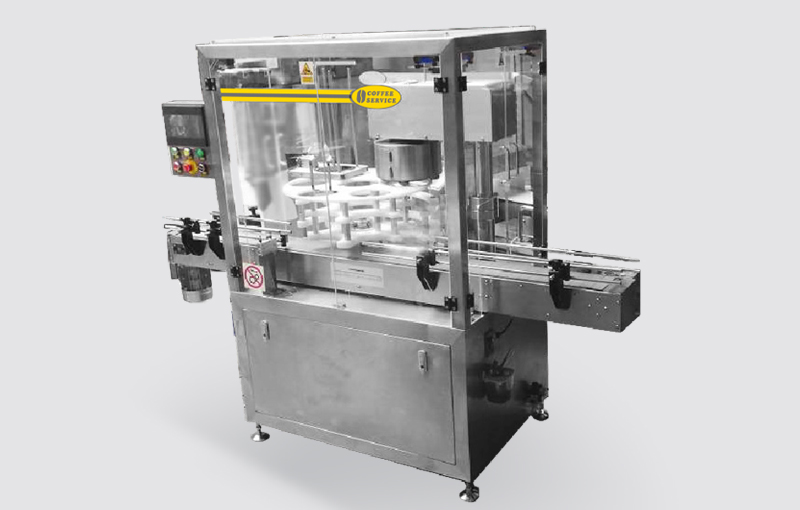

FILLERS FOR PACKING MACHINES

Thick liquid filler

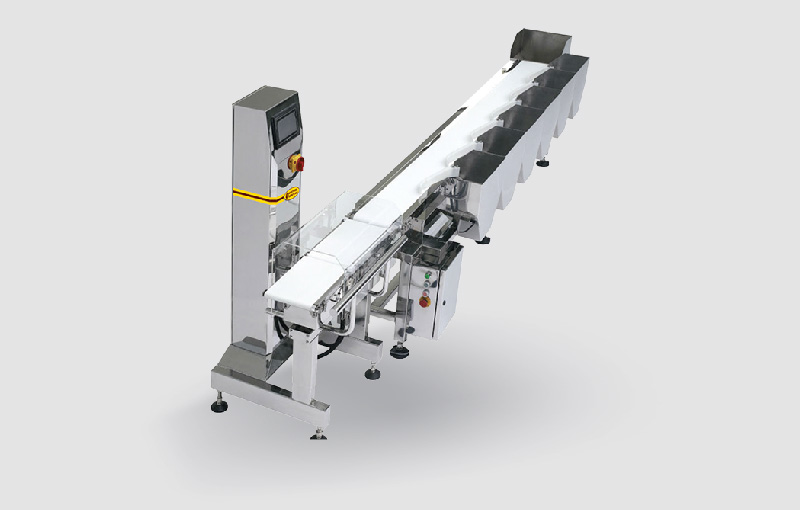

Combination weigher

Auger filler

POSSIBILITY OF MANUFACTURING DEVICES | ||||

STANDARD MACHINES |

Packaging machine COFPACK P/S 70/620

Packaging machine COFPACK P/S 180/510 CONTINUOUS

Packing on the machine with different speeds.

Packaging machine P/S 70/620 + DS/S 3000 + PSM 2600 + OGT/S 300 + KW 1000

Packaging machine P/S 50/600 EKO + PWK 2000 + PRZ 3750 M + DWK 10 + OGT/S 300

Packaging machine P/S 50/600 EKO + PRZ 3250 + SWK + DWK 8 + OGTL/S

Packing line for candy-floss

P/S 60/500 EKO + candy-floss forming conveyor + OGT/S 300

Packaging machine P/S 90/400 + OGT/L 250 + DWK 10 + FRAME SWK

Related Products and Services

Contact us

Our consultants will be happy to answer all your questions

and advise you on choosing the right products and services.