New

|

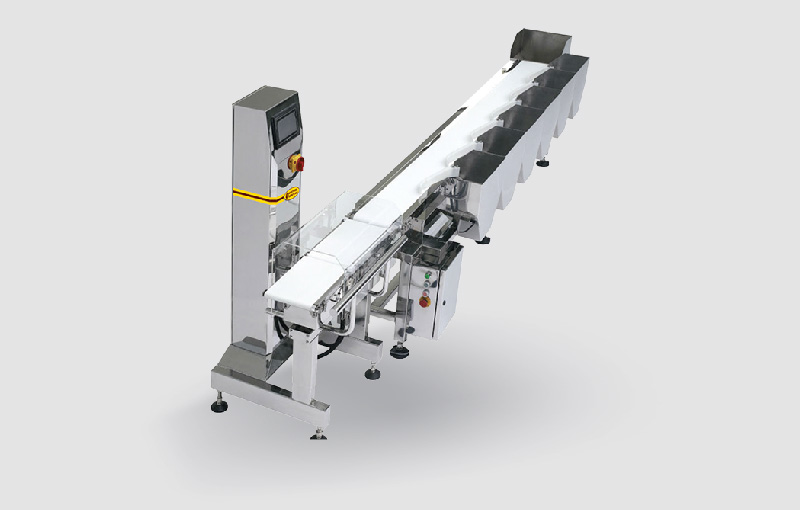

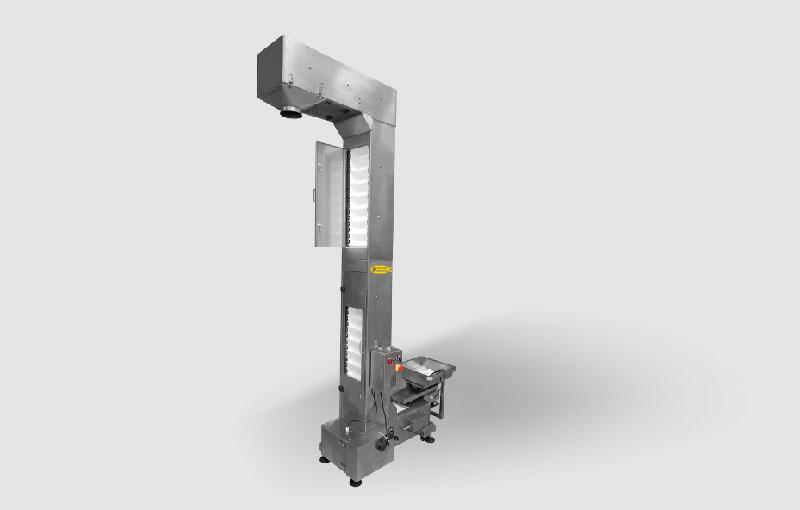

The filling system for weighing toy building blocks is an integral part of the production process, ensuring precise measurement and packaging of blocks into boxes according to predetermined weight specifications. This system is designed not only to automate the packaging process but also to guarantee uniformity and quality of the final product, which is crucial for customer satisfaction and maintaining production standards.

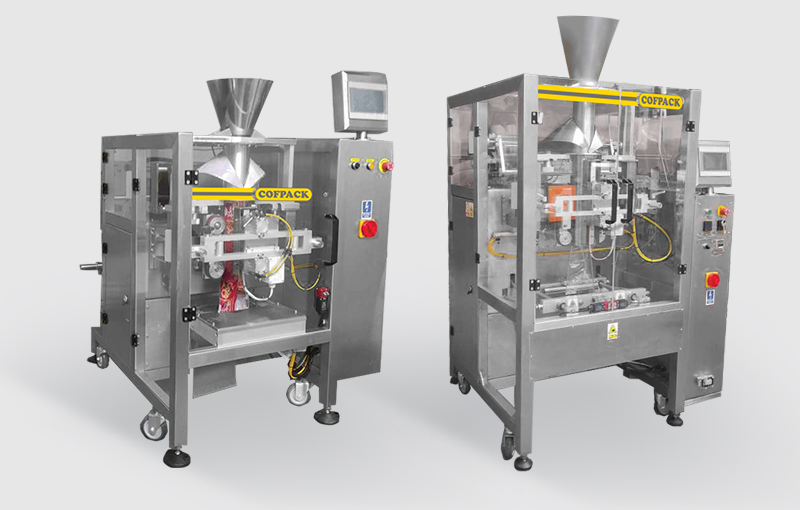

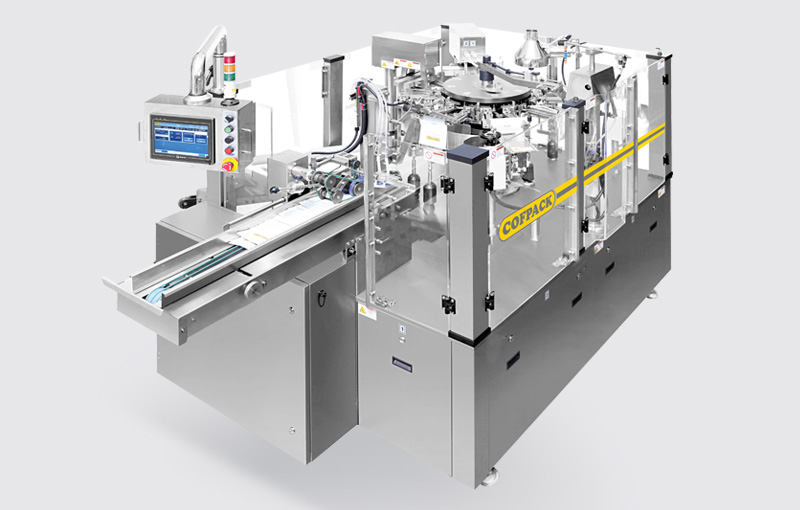

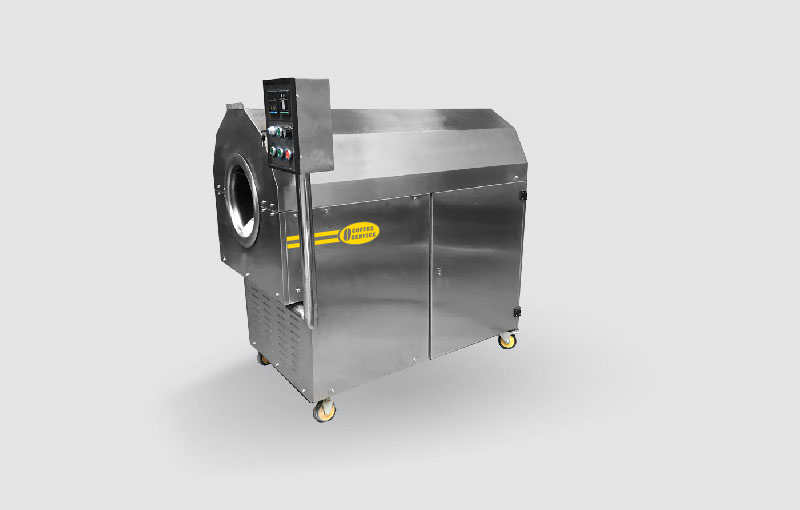

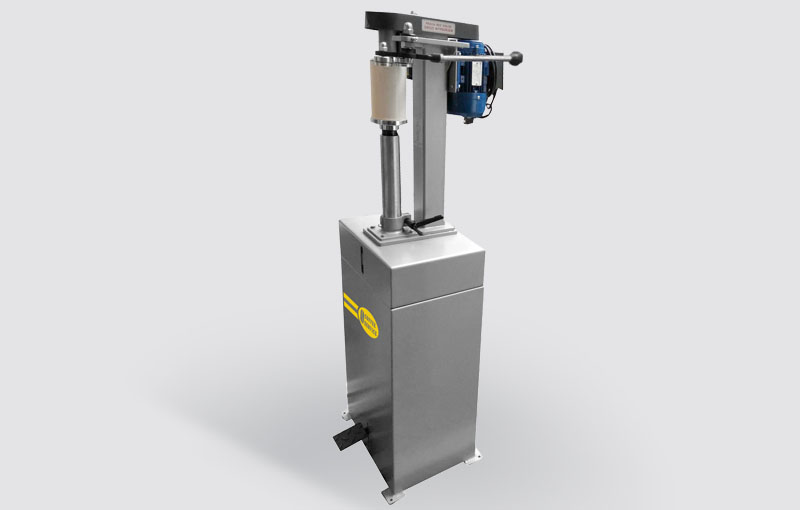

Key Features of the Filling System:Precise Weighing:The filling system is equipped with modules that accurately measure the quantity of blocks to be placed in each box. This ensures that every package contains exactly the same amount of blocks, eliminating the risk of underweight or overweight packages. Process Automation:Automatic filling systems minimize the need for manual block packaging, increasing production efficiency and reducing labor costs. Automation also allows for increased production speed, enabling the fulfillment of larger orders. Quality Control:Filling systems can be equipped with additional features such as sorting and removing damaged or non-compliant blocks before packaging. This ensures that only high-quality products reach customers. Integration with the Production Line:The filling system is often integrated with other elements of the production line, such as molding machines, coloring systems, as well as packaging and labeling systems. This coordination optimizes the entire block production process. Scalability:Modern filling systems are scalable, meaning they can easily adapt to changing production needs, such as different batch sizes or the introduction of new products. Benefits of Using the Filling System:Product Uniformity:Every box of blocks contains exactly the same amount of product, which is crucial for customer satisfaction and maintaining quality standards. Time and Cost Savings:Automating the packaging process reduces the time needed for manual packing and minimizes the risk of errors, leading to cost savings. Increased Productivity:Fast and precise block weighing allows for the production of a greater number of packages in less time, which is advantageous when fulfilling large orders. Better Inventory Management:Thanks to precise measuring, inventory management of blocks becomes more efficient, minimizing the risk of shortages or surpluses. Application Examples:In large factories producing toy blocks, such as LEGO or other popular brands, filling systems are an indispensable part of the production lines. These systems enable the quick and precise packaging of millions of blocks daily, ensuring continuity of supply and customer satisfaction worldwide. In conclusion, the filling system for weighing toy blocks is an advanced system that plays a key role in the toy production process, ensuring precision, efficiency, and high quality of the final product. #PackagingMachines #PakowanieProduktów #UkladZasypowy #AutomatDoPakowaniaKlocków |

If you have any questions, please use the contact form